so the other day i was testing my water and i noticed that my nitrates were starting to go up a little bit. they’re at 10 ppm now which i know people say isn’t too too bad, but i still am not comfortable with it. I’ve been regular with my water changes, but i wanted to start doing a little more, so i decided to start researching de-nitrators. then i found a large following on this topic of DIY coil de-nitrators. Any time i have the opportunity to combine my two favorite hobbies (building gadgets and <) i tend to hop on it. Of course, this weekend I had a whole bunch of stuff i needed to do, so i did what any responsible person would and ignored them all to take care of my tank. anyway, in a few hours of work, here’s what i came up with…

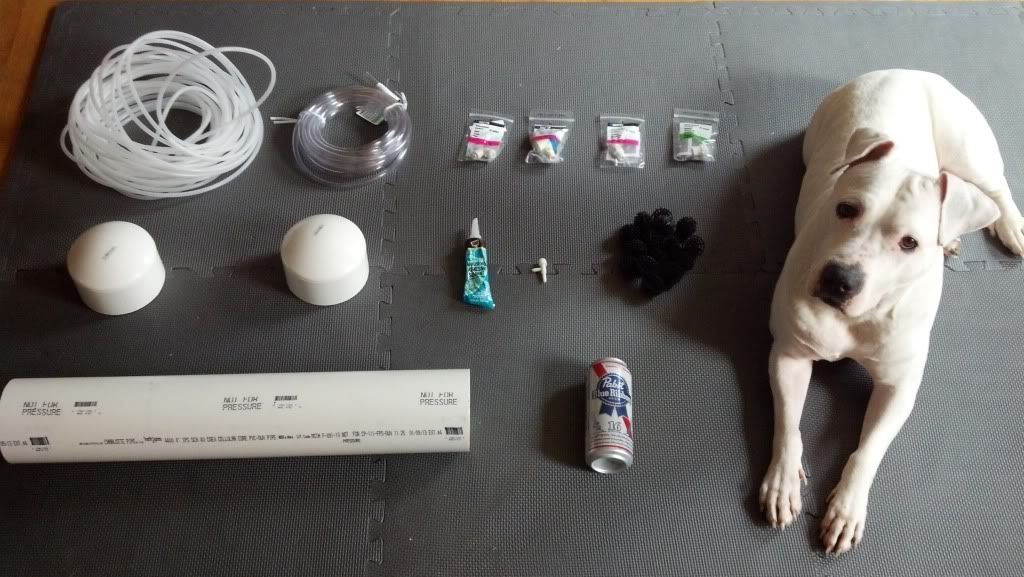

Total supply cost ~$40

80’ coiled 1/4" O.D. tubing. The duct tape is to hold the end in place as i continued to coil. This was the most laborious part of the project. Some people said they heated the tube up first to make it more pliable, but i bought the last continuous segment Lowe’s had and HD doesn’t sell it in custom lengths so i didn’t wanna mess it up.

Coils Completed.

90 elbow added to the bottom end of the tubing. This will force the water to start by flowing into the chamber downwards to elongate contact time.

Tapping holes for inlet and outlet.

connections threaded and siliconed. Unfortunately, after leak testing, i discovered the outlet valve leaks from the top of the valve body. I guess maybe they’re not meant to be mounted vertically. Either way, i had to replace it with a regular connection like the inlet has, which was unfortunate because it did an excellent job of controlling flow when it wasn’t leaking.

chamber filled with bioballs and coil siliconed to the inlet connection

chamber sealed up and quality assurance inspector giving the final look over. It’s important to note that once these babies are sealed, they’re sealed for good.

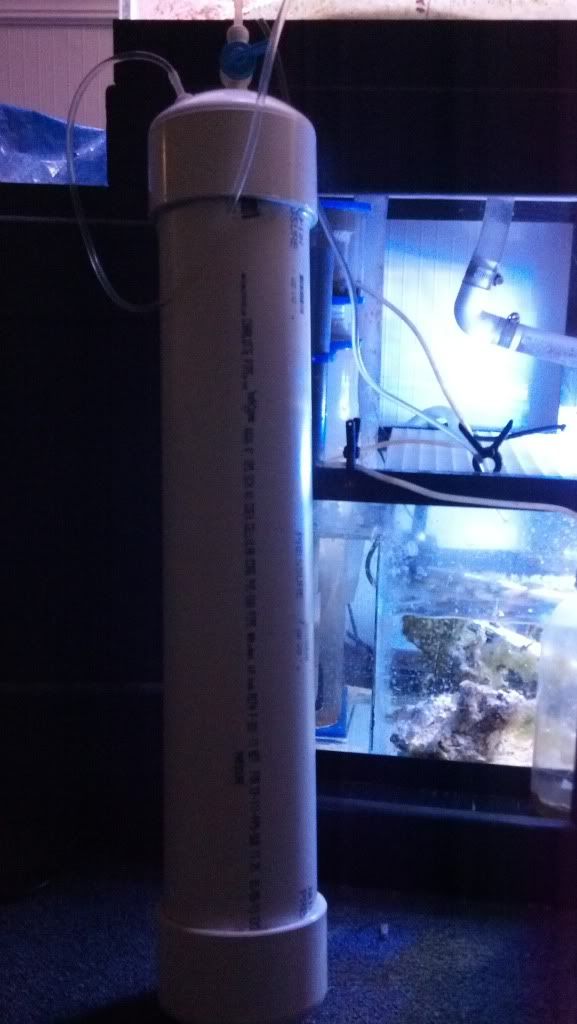

leak testing the final product. This is where i discovered the valve body leak. But once it’s finally set up, this is how it’ll be. It will take suction from the overflow area and discharge into the sump. The project is completely gravity fed and obviously silent, which is what attracted me to the project in the first place. No maintenance, no added power costs and no noise. And with the success that so many people seemed to have with them, I figured it was worth the time.

So now we wait. From what i’ve been told, it takes about two weeks to be fully cycled and then another month or two to completely remove the nitrates from the system. So there will be updates to follow. But from then on, there’s nothing to it. Set it and forget it. So fingers are crossed.